Force-Feedback Teleoperation

TeleRobotics EXtender™

TREX: The Haption Generic Teleoperation Controller for Easy Integration in Controlling Industrial Robots

TeleRobotics EXtender (TREX) is a framework designed for force-feedback teleoperation. It offers an innovative solution for situations where operators must operate in hazardous, challenging, or restricted environments, enabling them to carry out tasks without exposing themselves to risk. With TREX, operators can manually control a remote robot with high dexterity and precision while also sensing the forces at play through the Virtuose force-feedback device.

TREX provides an immediate solution for integrating teleoperation with a force-feedback device in a robotic system.

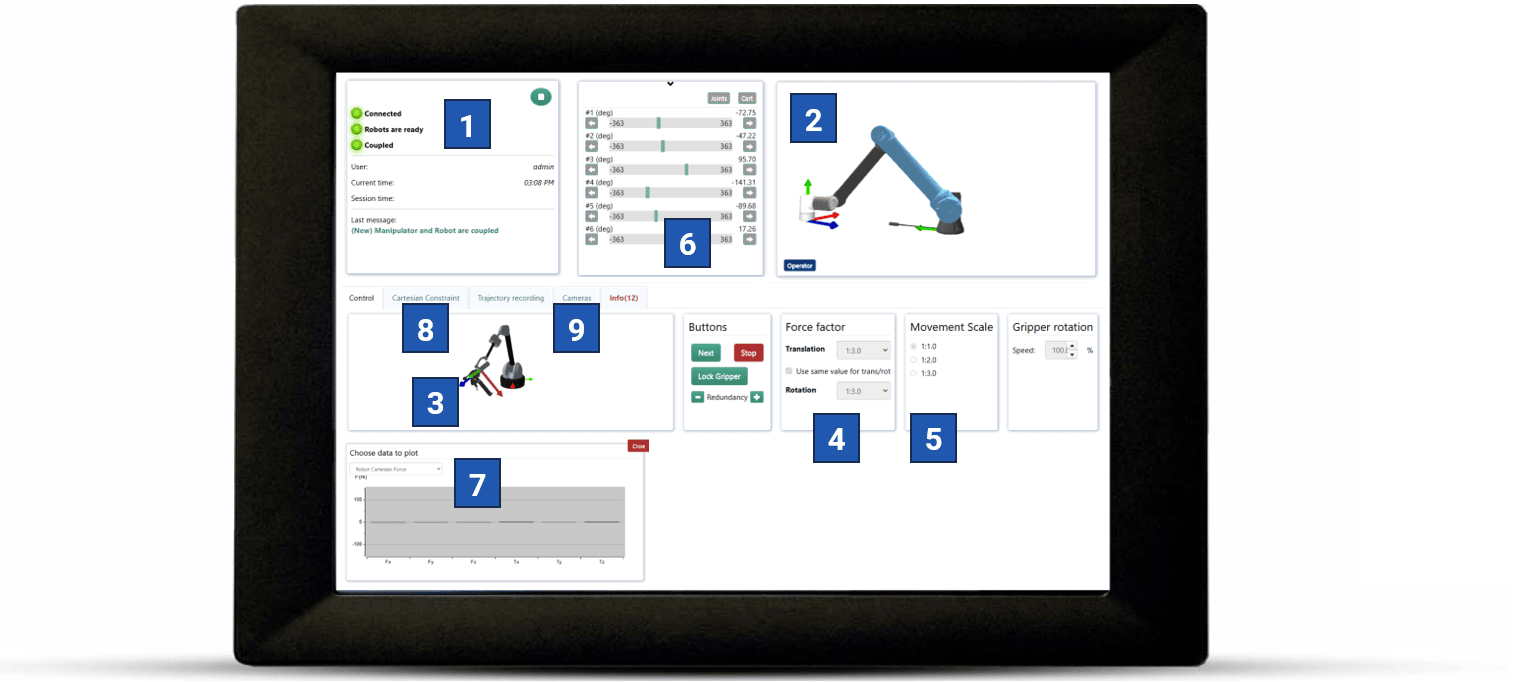

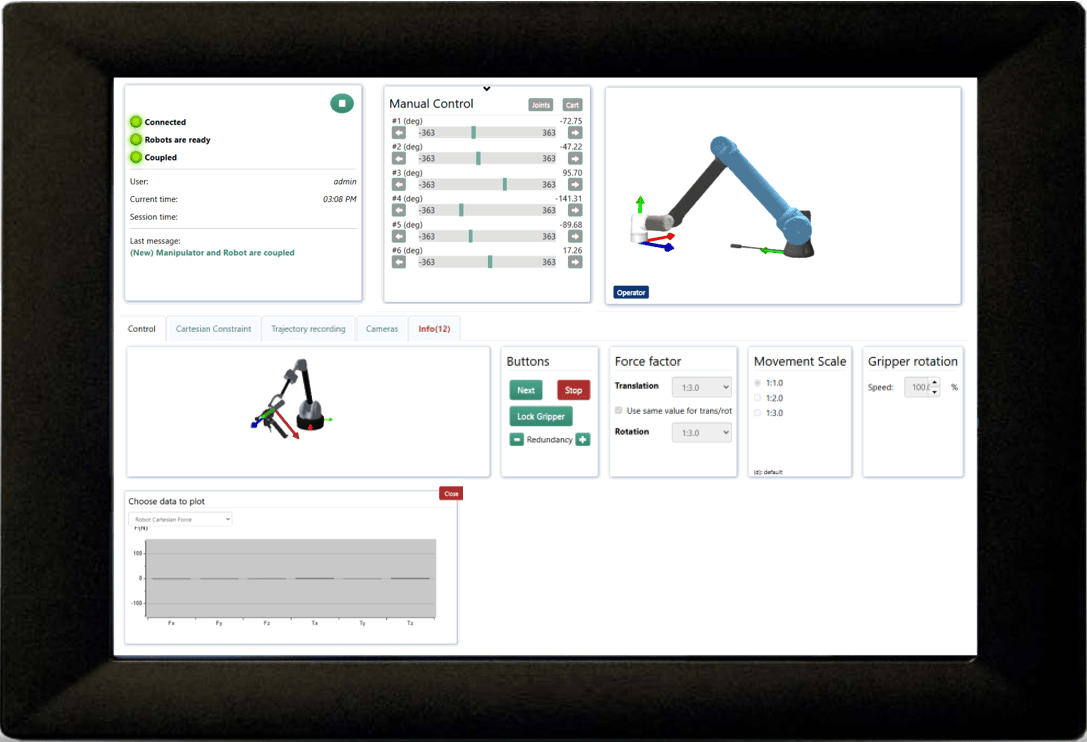

Pratical & intuitive Human Machine Interface

Visualization of the teleoperation status

Real time 3D visualization of robot

Real time 3D visualization of the force-feedback device

Control box for the force feedback ratio

Control box for the movement ratio

Visualization of each robot axis position, with manual control capability

Visualization of robot effort and torque

Guiding feature for the operator, using cartesian constraints

Selection of the point of view for the operator, when using static and dynamic cameras

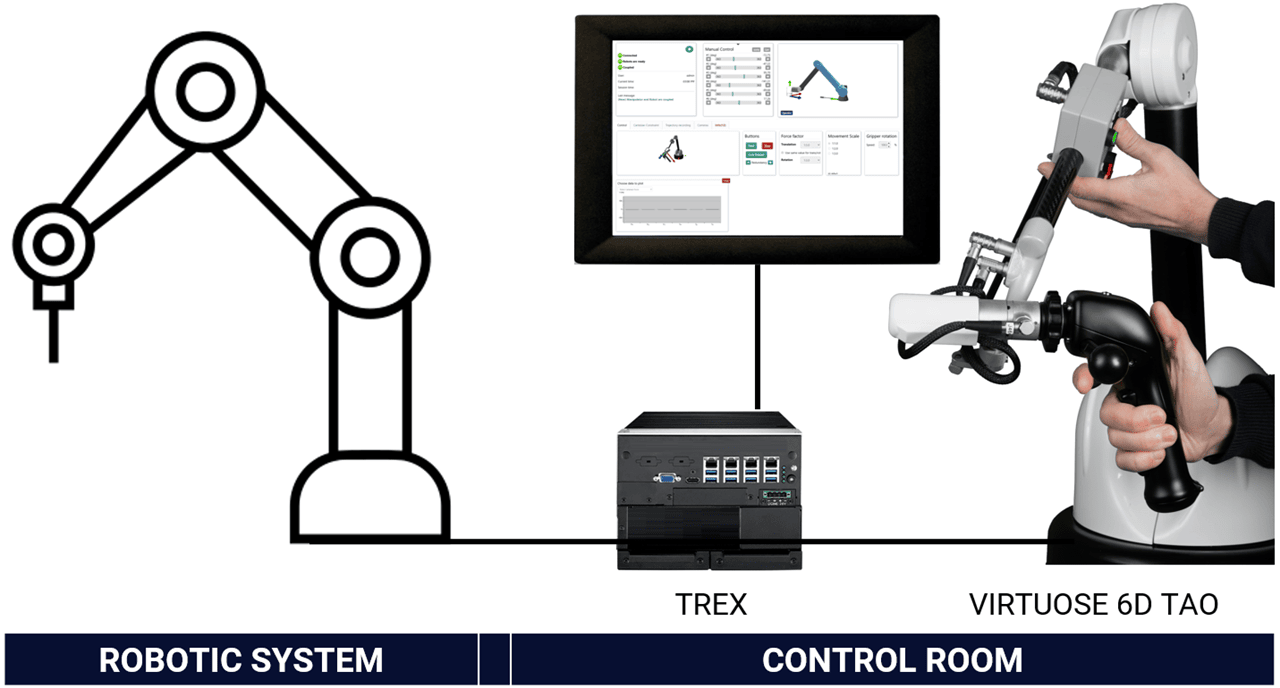

•The solution, known as a telerobotic solution, consists of the following components:

A Haption force-feedback device, the VIRTUOSE 6D HF TAO or the VIRTUOSE 6D TAO, the manipulator, which can connect via Ethernet or EtherCAT.

A Haption generic teleoperation controller device, called “TREX,” operating on a ruggedized hardware controller.

This solution can connect to third-party vendor robots, including Fanuc™, Kuka™, ABB™, Stäubli™, Doosan™, Universal Robots™, Franka™, Agile Robotics™, Kinova™, and more. (Please inquire about compatibility with your specific robot.)

Additionally, the system is designed to accommodate third-party robot tools on the end-effector, such as grippers for grasping and manipulation or other tools for tasks like cutting, grinding, or unscrewing.

Operators can work with the force-feedback manipulator close to or far from the robot, depending on the use case.

Thanks to force-feedback technology, the operator feels the robot's dynamics and the forces it applies. This force sensation is crucial for minimizing the risk of damage to the environment or the robot itself. The robot faithfully replicates the movements of the manipulator, making it feel like an extension of the operator's hand.

By using the manipulator, operators can work comfortably while retaining all their manual skills without being exposed to hazardous or restrictive environments. The manipulator also allows users to sense the robot's dynamics, including the weight of grasped objects and any potential collisions.

A set of buttons enables operators to adjust parameters such as the robot's scale of force and movement.

In summary, TREX provides an ideal solution for:

Reducing operator exposure to environmental risks while allowing precise control of robot movements and enhancing dexterity.

Maximizing the use of operators' manual skills and cognitive abilities.

Ensuring that the human operator remains in charge of all decision-making.

With TREX, operators continue to bring their expertise and manual skills through the robot in real-time without the need of programming.

TREX enables the user to take control of their own telerobotic system in no time, because it has been designed to be a “No Code” solution.

Among of the TREX Features

Haption provides a proven solution and drives innovation with a roadmap fed by customers’ needs.

Immediate & Intuitive Control with No Code

OPC-UA interface, the Industry 4.0 standard for data exchange (IEC62541)

Operator Camera(s) View(s) Management

Operator Guidance Features

TREX list of the supported robots

Robots with force sensor

UNIVERSAL ROBOTS

UR20 | UR10e | UR16e | UR5e | UR3e (UR30)

DOOSAN

H2017 (H & M ranges)

KUKA

KR20 (KR serie)

FANUC

M20iD25

AGILE ROBOTS

DIANA 7

FRANKA ROBOTICS

FRANKA RESEARCH 3

KINOVA

KINOVA GEN3 in 6DOF & 7DOF

Robots without force sensor

STAUBLI

TX2 40 | 60 | 160 (90 | 140 | L type)

KAWASAKI

RS015X

KUKA

KR16 | KR20 | KR120 | KR240 (KR series)

FANUC

M20iD25 | M20iD35 | M710 | R2000

OEM robots

JRC Karlsruhe

MA23

Is your robot not on the list?

Haption could work with other makes of robot, please get I touch and tell us what you need.

Bundle Kits “VIRTUOSE + TREX” Ready to Go!

With our bundle offer, you are ready to take control of your own telerobotic system in no time!

UNIVERSAL ROBOTS

UR20 | UR16e | UR10e | UR5e | UR3e

DOOSAN

H2017

FRANKA ROBOTICS

Franka Research 3

KINOVA GEN3

in 6 & 7 DOF

AGILE ROBOTS

Diana 7

Discover customers applications

Haption products are used by engineers to solve industries challenges in various fields such as nuclear, and laboratory.

And now with the boom of robotics in all industries, Haption products are also used to improve operators working conditions and employability.

Haption products are used by researchers to focus on project key challenges.